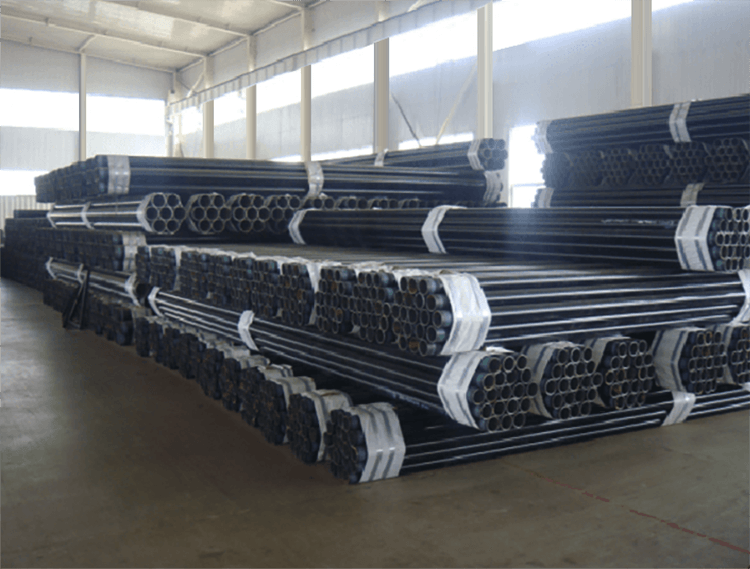

2PE/3PE Corrosion Structure: The steel surface electrostatic spraying, epoxy powder and binder twine lateral wound polyethylene coating, combined with three excellent performances, thereby significantly improving the overall quality of anti-corrosion of the pipe.The coating is made of hot-melt epoxy powder (FBE) as the bottom layer (2LPE/PP epoxy powder without bottom layer), ethylene/propylene copolymer cavity adhesive (AD) as the middle layer, and high-density polyethylene(PE)/propylene (PP) as the three-layer structure anticorrosive coating.This structure is mainly used for FBE’s high adhesion, oxidation resistance, chemical corrosion resistance, excellent cathodic peel resistance and high density poly (ethylamide) and acrylic acid resistance.Anti – aging, insulation and anti – mechanical damage performance of a perfect combination.

Size OD: 20-1000 mm

Thickness: 1-80 mm

Length: Random Length, Fixed Length, SRL, DRL

Standard: API 5L / ASTM A53-2007 / ASTM A106-2006 / BS1139 / BS1387

Material: ChineseGrade Q215, 0235, 10# 20# according to GB/1700; Q345 According to GB71591

Foreign Grade: ASTM Grade B, Grade C, Grade D, Grade 50

EN: S185, S235JR, S235JO, E335, S355JR, S355J2

JIS: SS330, SS400, SPFC590

Process Range: The basic coated steel pipes including spiral, straight seam pipe, seamless steel pipe, etc. They are widely used in pipeline projects in the field of petroleum, chemical, natural gas, heating, sewage treatment, water, bridges, steel structure, pilling and marine construction.

Ends: Plain, Beveled, Thread With Couplings Or Sockets; Plastic Caps And Steel Rings Can Be Provided if possible

Inspection: With Chemical Composition and Mechanical Properties Analysis; Dimensional and Visual lnspection, Also with Non-destructive Inspection